Spirax Sarco DEP4 Cast Steel Relief Valve

Brand authorization

- Rapid response service

- Professional team support

- Flexible return and exchange policy

Spirax Sarco Spirax Sarco DEP4 cast steel relief valves are cast steel body direct acting bellows sealed relief valves. The standard version has an EPDM diaphragm (max. operating temperature 125°C) and is suitable for water and steam systems. Nitrile rubber diaphragms (suffix "N", maximum operating temperature 90°C) are also available for oil systems. Note: In steam systems, a WS4 water seal tank must be used on the upstream pressure sensing tube to protect the actuator diaphragm, see TI-S12-03.

(an official) standard

The products are fully compliant with the European Pressure Equipment Directive 97 / 23 / EC, with marking on request.

Certification

As standard, products are supplied with manufacturer's typical test certificates. EN 10204 3.1 certificates are available on request. Note: The required certificates and test requirements need to be specified when placing the order.

Available Models

DN15-DN100 flange connection, 6 pressure ranges (suffix 1-6).

Upstream pressure range

| realm | Valve Model | Actuator Model | Spring Color | DN15 - DN40 pressure range (bar) | DN50 - DN80 pressure range (bar) | DN100 pressure range (bar) | PN Rating |

|---|---|---|---|---|---|---|---|

| 1 | DEP4B1 | 11 or 11N | pornographic | 0.1 - 0.5 | 0.1 - 0.3 | 0.1 - 0.3 | 2.5 |

| 2 | DEP4B2 | 12 or 12N | pornographic | 0.2 - 0.8 | 0.2 - 0.5 | 0.2 - 0.5 | 2.5 |

| 3 | DEP4B3 | 13 or 13N | indigo plant | 0.5 - 1.7 | 0.4 - 1.3 | 0.4 - 1.0 | 6 |

| 4 | DEP4B4 | 14 or 14N | indigo plant | 1.4 - 3.4 | 1.0 - 2.6 | 0.8 - 2.5 | 16 |

| 5 | DEP4B5 | 15 or 15N | indigo plant | 3.2 - 7.5 | 2.3 - 5.5 | 2.3 - 5.0 | 25 |

| 6 | DEP4B6 | 15 or 15N | bonus | 7.0 - 16.0 | 5.0 - 15.0 | 4.0 - 10.0 | 25 |

Sizes and pipe connections

DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80 and DN100 flanges: EN 1092 PN40. On request: JIS and ANSI 150, ANSI 300 flanges.

Pressure/Temperature Limits

| ontology | PN40 |

|---|---|

| PMA Maximum Allowable Pressure | 40 bar g @ 50°C |

| TMA Maximum Allowable Temperature | 300°C @ 25.8 bar g |

| Minimum design temperature | 0°C |

| TMO EPDM Diaphragm Maximum Operating Temperature | 125°C |

| Nitrile rubber diaphragm maximum working temperature | 90°C |

| Minimum operating temperature (ambient) | 0°C |

| PMX Maximum Working Differential Pressure | DN15 - DN50 25 bar; DN65 - DN100 20 bar |

| Design maximum cold hydraulic test pressure | 60 bar g |

| classifier for sums of money | The test pressure should not exceed 40 bar g after installation of the internal components. |

Kvs value

| Caliber DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

|---|---|---|---|---|---|---|---|---|---|

| Kvs | 3.4 | 6.5 | 11.4 | 16.4 | 24 | 40 | 58 | 92 | 145 |

Note: The above KVS value is the value when the valve is fully open and is used for safety valve selection.

material (that sth is made of)

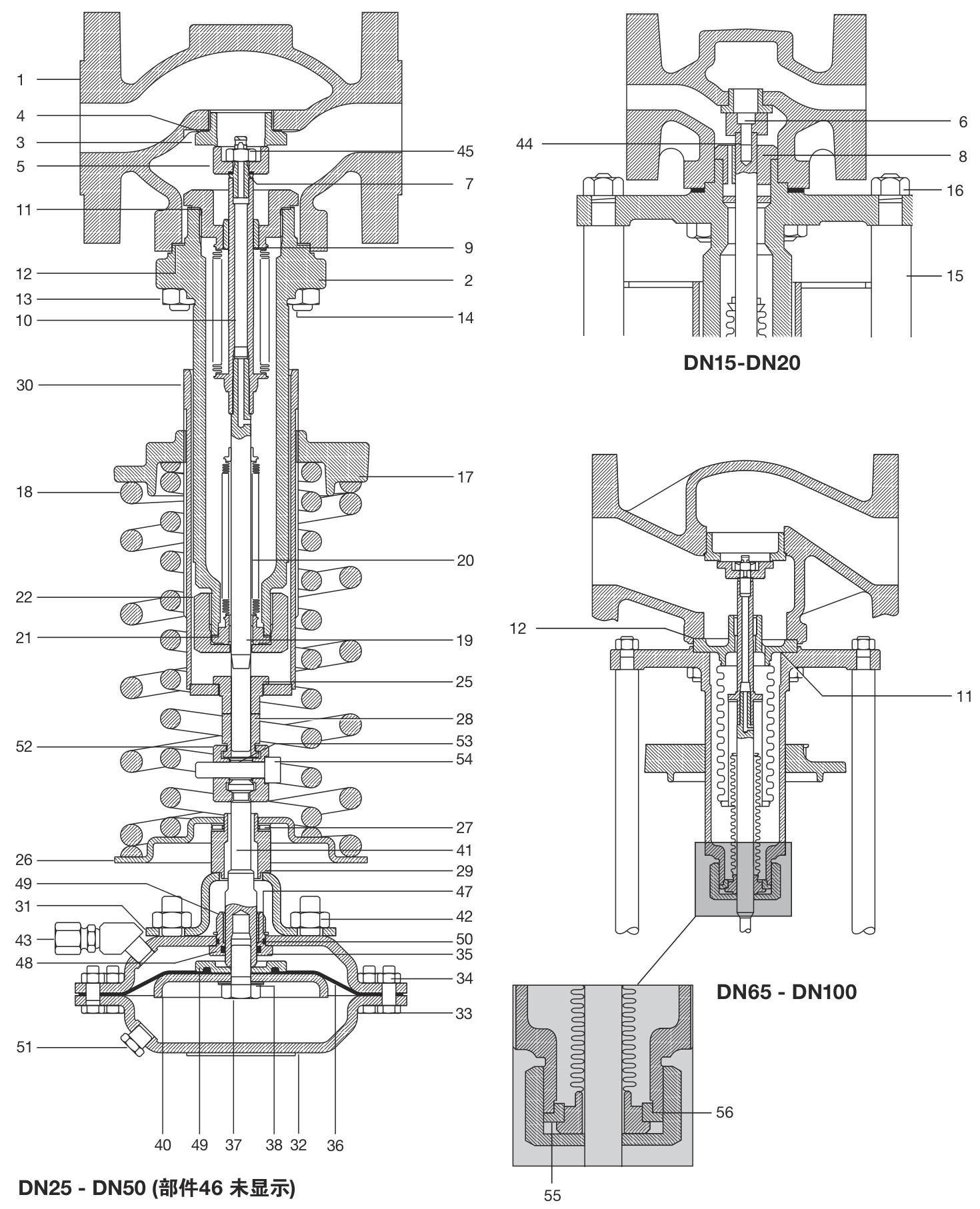

| Item | Part | material (that sth is made of) |

|---|---|---|

| 1 | valve body | Cast steel GP 240 GH |

| 2 | bonnet | Cast steel DIN 17245 GSC25 |

| 3 | Seat | Stainless steel BS 970 431 S29 |

| 4 | Seat gasket | DN15: stainless steel; DN20 and DN25: mild steel; DN32 - DN50: reinforced flake graphite |

| 5 | spool | Stainless steel BS 970 431 S29 |

| 6 | Spool Bolt | DN15 and DN20: stainless steel BS 6105 A2 |

| 7 | Spool Seal | DN15 and DN20: Arlon 1555 |

| 8 | bushing | Stainless steel BS 970 431 S29 |

| 11 | Balanced Bellows Assembly Gasket | DN25 - DN100: Reinforced flake graphite |

| 12 | Cap Gasket | Reinforced flake graphite |

| 13 | Bonnet bolts | DN15 - DN40 M10: Steel DIN 267 Pt13 Gr. 8 |

| 14 | DN50 and DN65 M12: steel DIN 267 Pt13 Gr. 8.8; DN80 and DN100 M16 | |

| 15 | mainstay | Galvanized steel BS 970 230 M07 |

| 16 | Pillar Nuts | Galvanized steel BS 3693 Gr. 8 |

| 17 | Spring Adjuster | Galvanized cast iron DIN 1691 GG25 |

| 18 | sprung | chrome-vanadium steel |

| 19 | Bearing (part of component 20) | PTFE / steel composite |

| 20 | Sealed Bellows Assemblies | Stainless steel AISI 316L |

| 21 | Sealing Bellows Gasket | DN15 and DN20: stainless steel 'S' type; DN25 - DN100: reinforced flake graphite |

| 22 | fixing nut | DN25 - DN100: galvanized steel BS 970 230 M07 |

| 25 | locknut | Galvanized steel BS 970 230 M07 |

| 26 | spring-loaded stopper | Galvanized steel BS 1449 Pt 1 HR14 |

| 27 | needle roller bearing | steel (chemistry) |

| 28 | Setting Nut | Galvanized steel BS 970 230 M07 |

| 29 | Bearing Locator | Galvanized steel BS 970 230 M07 |

| 30 | Regulator Sleeve | galvanized steel |

| 31 | Mounting Stalls | Types 11(N) - 14(N): Galvanized steel BS 1449 Pt 1 HR14 DIN 1514 St W24 |

| 32 | housings | Type 15(N): Steel BS EN 10025 S355 J2G3 |

| 33 | Housing bolts | Types 11(N) - 12(N): galvanized steel BS 3692 Gr. 5.6; Types 13(N), 14(N) and 15(N): galvanized steel BS 3692 Gr. 8.8 |

| 34 | Housing Nut | Types 11(N) and 12(N): galvanized steel BS 3692 Gr. 5.6; Types 13(N), 14(N) and 15(N): galvanized steel BS 3692 Gr. 8 |

| 35 | crown bar guide | Stainless steel BS 970 431 S29 |

| 36 | diaphragm | EPDM or Nitrile Rubber |

| 37 | hexagonal screw | Stainless steel BS 6105 A2 |

| 38 | sealing gasket | fibroid |

| 39 | diaphragm clamp | Stainless Steel ASTM A351 CF8M |

| 40 | pistons | Galvanized carbon steel BS 1449 Pt 1 HR14 |

| 41 | top bar | Galvanized carbon steel BS 970 230 M07 |

| 42 | mounting nut | Galvanized steel BS 3692 Gr. 8 |

| 43 | pipe fitting | galvanized steel |

| 44 | Threaded Inserts | DN15 and DN20: stainless steel DTD 734; DN25 - DN100: galvanized steel BS 1449 CR4 |

| 45 | Self-locking nuts | Galvanized steel BS 1449 CR4 |

| 46 | spread litter in a cowshed, pigsty etc | Type 12(N) only: galvanized steel |

| 47 | spring ring | galvanized steel |

| 48 | Top Rod Seal 'O' Ring | EPDM or Nitrile Rubber |

| 49 | bear the weight of (a building) | PTFE/steel composite |

| 50 | Housing seal 'O' ring | EPDM or Nitrile Rubber |

| 51 | bleeder plug | plastics |

| 52 | coupling clip | Galvanized steel ASTM A216 Gr. WCB |

| 53 | sprung | Spring steel BS 5216 Gr. M4 |

| 54 | set screw | Galvanized steel BS 4168 Gr. 12.9 |

| 55 | retaining plate | DN65 to DN100 only: Stainless steel ASTM A276 316L |

| 56 | Sealing Gasket | Reinforced flake graphite |

Sizing for Steam Applications

Use the selection table to determine the valve Kv for steam applications through; - upstream pressure - maximum valve pressure drop - maximum steam load. Knowing the valve Kv, the valve pressure drop at any given flow rate can be determined.

Selection of water applications

Use the selection table to determine the valve Kv for steam applications through; - Maximum flow rate - Maximum valve pressure drop. Knowing the valve Kv, the valve pressure drop at any given flow rate can be determined.

Spare Parts

Spare parts available (DN15 to DN20)

| connection | A |

|---|---|

| Diaphragm assemblies (diaphragms and gaskets) | B, C |

| needle roller bearing | D |

| Sealed Bellows Assemblies | Seal bellows, bellows gasket, bonnet gasket: E, F, G, H |

| Control springs | I |

| Seat/spool assembly | Seats, seat gaskets, spool and bonnet gaskets: J, K, L, G, H |

| Gasket set | Sealing bellows gaskets, bonnet gaskets, and seat gaskets: F, G, K |

| Actuator rod guide set | Shaft guides, bearing bushings, shaft sealing 'O' rings, cavity sealing 'O' rings and retaining rings: P, R, S, T, V |

Spare parts available (DN25 to DN100)

| connection |

|---|

| Diaphragm assemblies (diaphragms and gaskets) |

| needle roller bearing |

| Sealed Bellows Assemblies |

| Control springs |

| DN25-DN50 seat/spool assemblies |

| DN65-DN100 spool assemblies |

| DN25-DN50 balanced bellows assembly |

| DN65-DN100 balanced bellows assembly |

| DN25-DN50 gasket set |

| DN65-DN100 gasket set |

| Actuator Bearing Assembly |

Ordering Spare Parts Order spare parts according to the instructions above, specifying the valve size and model number. Example: 1-gasket set for DN 25 DEP4B1 relief valve.

mounting

Detailed installation instructions are provided in the installation and maintenance guide supplied with the spare part.

weights

Valve weight (kg)

| Valve Caliber | DN15 | DN20 | DN25 | DN32 | DN40 | DN50 | DN65 | DN80 | DN100 |

|---|---|---|---|---|---|---|---|---|---|

| Yellow spring weight | 11.6 | 13.3 | 16.7 | 21.4 | 23.7 | 26.3 | 37.7 | 46.0 | 69.8 |

| Blue Spring Weight | 11.6 | 13.3 | 16.7 | 21.4 | 23.7 | 26.3 | 37.7 | 46.0 | 69.8 |

| Red spring weight | 13.6 | 14.8 | 18.2 | 22.9 | 25.2 | 27.8 | 39.4 | 47.7 | 72.5 |

Actuator weight (kg)

| Actuator Model | 1 or 1N | 2 or 2N | 3 or 3N | 4 or 4N | 5 or 5N |

|---|---|---|---|---|---|

| weights | 12.3 | 6.5 | 4.0 | 2.6 | 2.7 |

Note: Total product weight equals the weight of the valve and actuator combined.

Security information, installation and maintenance

See the Installation and Maintenance Guide supplied with the product for detailed information. (IM-S12-10)

NOTE: When applied to steam systems, to protect the actuator diaphragm, a WS4 water seal tank should be installed upstream and connected to the actuator by a sensing tube. See TI-S12-03 for details.This valve should be installed vertically downstream in horizontal piping, ensuring that the direction of flow is as indicated by the arrow on the valve body. The valve can also be installed vertically upwards when the upstream temperature is below 125°C.

Order Installation

Example: 1 - Spirax Sarco DN40 DEP4B3 direct acting relief valve, Flanged, PN40. Note: Add suffix 'N' if Buna N diaphragm is required, also DEP4 B3N.