Spirax Sarco Spirax Sarco BTD52L Thermodynamic Steam Trap

原价为:¥8,164.00。¥2,700.00当前价格为:¥2,700.00。

Brand authorization

- Rapid response service

- Professional team support

- Flexible return and exchange policy

Spirax Sarco BTD52L Thermodynamic Steam Trap in 316L Stainless Steel for Steam Main Traps in Clean Steam Systems.

Standards and Certificates

This product is fully compliant with the European Pressure Equipment Directive 2014/68/EU and can be supplied with a certificate EN 10204 3.1 (please specify when ordering if a certificate is required).

Sizes and pipe connections

- ¼", 3/8", ½" BSP or NPT threaded connections.

- ½" OD x 16 swg (0.065") wall thickness tube end connections.

- DIN 11850 (series1) pipe ends: 12mm OD x 1.0mm wall thickness (DN 10), 18mm OD x 1.0mm wall thickness (DN 15).

- ISO 1127 (series1) pipe ends: 17.2mm OD x 1.6mm wall thickness (DN 10), 21.3mm OD x 1.6mm wall thickness (DN 15).

- ½" sanitary clamp connection (DN15).

selectable

The heat shield protects the trap from excessive heat dissipation caused by severe weather conditions such as rain, wind, and low temperatures.

Pressure/Temperature Limits

| sports event | particulars |

|---|---|

| Valve body design conditions | PN16 |

| PMA Maximum Allowable Pressure | 16 bar g @ 50 °C |

| TMA Maximum Allowable Temperature | 450 °C @ 8 bar g |

| Minimum permissible temperature | 0 °C |

| PMO Maximum Working Pressure under Saturated Steam | 10 bar g @ 220 °C |

| TMO Maximum Operating Temperature | 450 °C @ 8 bar g |

| Minimum working temperature | 0 °C (lower operating temperatures, consult Spirax Sarco) |

| PMOB | Maximum working back pressure not to exceed 80% of upstream pressure |

| Minimum working differential pressure | 0.25 bar g |

| Design maximum cold hydraulic test pressure | 24 bar g |

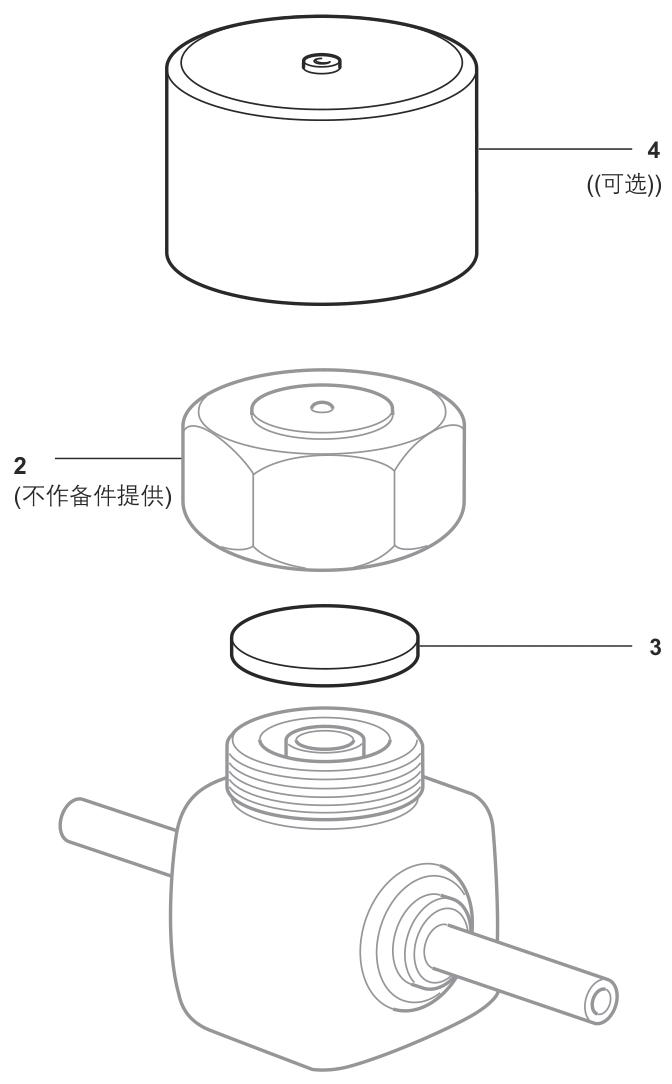

material (that sth is made of)

| Item | Part | material (that sth is made of) |

|---|---|---|

| 1 | valve body | Austenitic stainless steel AISI 316L |

| 2 | bonnet | Austenitic stainless steel AISI 316L |

| 3 | compact disc | Austenitic stainless steel AISI 316L |

| 4 | Isolation cover (optional) | aluminum (chemistry) |

weights

| caliber | Sanitary clamps/BSP or NPT | pipe end |

|---|---|---|

| All calibers | 0.45kg | 0.55kg |

engine displacement (volume of air fuel mixture drawn in during one cycle)

Displacement charts: (charts are omitted here; the original article has corresponding charts showing condensate volumes at different pressure differentials)

Security information, installation and maintenance

For detailed information, refer to the Installation and Maintenance Guide (IM-P181-03) supplied with the product. It is best to install horizontally with a section of drop pipe in front of the trap. The BTD52L can also be installed vertically where it is freezing or where horizontal installation is not possible, but this may affect its service life. Shut-off valves should be provided at the front and rear of the trap for ease of maintenance and replacement. If the trap discharges into a closed recovery system, a check valve should be provided downstream of the trap to prevent fluid return.

deal with

This product is recyclable and does not cause environmental problems when disposed of properly.

Ordering Instructions

Example: 1 - Spirax Sarco BTD52L Thermodynamic Steam Trap, 316L Stainless Steel Body, Pipe End Connection 17.2mm OD x 1.6mm Wall Thickness (ISO 1127, Series 1).

Spare Parts

Spare parts available: disks, heat shields.

Ordering Spare Parts: Please order spare parts according to the above instructions, indicating the trap type and size. Example: 1-Disc assembly for Spirax Sarco BTD52L ½" BSP thermodynamic steam trap.