Spirax Sarco TDS46M Stainless Steel Thermodynamic Steam Trap with Replaceable Seat

Brand authorization

- Rapid response service

- Professional team support

- Flexible return and exchange policy

The Spirax Sarco TDS46M replaceable seat stainless steel thermodynamic steam trap is specially designed for small capacity applications up to 46 bar g. It is available with threaded, socket weld or integral flange connections.

This trap has the advantages of a built-in strainer, built-in drain valve, heat shield, and replaceable valve seats. Optionally, the BDV1 integral drain valve can be installed on the strainer cover, please specify if you want to order.

Standards and Certificates

This product complies with the European Pressure Equipment Directive 97/23/EC and is supplied with an EN 10204 3.1 certificate. Note: If a certificate is required, please specify when ordering.

Sizes and pipe connections

- ½", ¾" & 1" Screwed BSP or NPT

- ½", ¾" and 1" socket welds, BS 3799 Class 3000 lb.

- DN15, DN20 and DN25 integral flanges EN 1092 PN40, PN100 and ASME class 150, ASME class 300 or ASME class 600

material (that sth is made of)

| Serial number parts | material (that sth is made of) |

|---|---|

| 1 | Valve Body: Stainless Steel 1.4308 / ASTM A351 CF8 |

| 2 | Bonnet: Stainless steel 1.4301 / ASTM A479 304 |

| 3 | Heat shield: stainless steel EN 10088-1 1.4301 |

| 4 | Disc: Hardened steel 1.2379 |

| 5 | Seat: Hardened steel 1.2379 |

| 6 | Bimetallic rings: Bimetallic |

| 7 | Support ring: stainless steel AISI 304 |

| 8 | Seat gasket: reinforced flake graphite |

| 9 | Filter: Stainless steel ASTM A478 316L |

| 10 | Filter cover gasket: stainless steel AISI 304 |

| 11 | Filter cover: stainless steel 1.4308 / ASTM A351 CF8 |

Pressure/Temperature Limits (ISO 6552) - Threaded, Socket Weld and Flanged EN 1092

| categorization | parameters | particulars |

|---|---|---|

| PN100 | Valve body design pressure | PN100 |

| PMA Maximum Allowable Pressure | 100 bar g @ 50°C | |

| TMA Maximum Allowable Temperature | 450°C @ 58.3 bar g | |

| Minimum permissible temperature | -50°C | |

| PMO Maximum Working Pressure | 46 bar g @ 450°C | |

| TMO Maximum Operating Temperature | 450°C @ 46 bar g | |

| Minimum working pressure | 0°C | |

| Minimum working temperature | 1.5 bar g | |

| Maximum working back pressure | Not to exceed 80% of upstream pressure | |

| Design maximum cold hydraulic test pressure | 150 bar g | |

| PN40 | Valve body design pressure | PN40 |

| PMA Maximum Allowable Pressure | 40 bar g @ 50°C | |

| TMA Maximum Allowable Temperature | 450°C @ 23.3 bar g | |

| Minimum permissible temperature | -50°C | |

| PMO Maximum Working Pressure | 28.4 bar g @ 233°C | |

| TMO Maximum Operating Temperature | 450°C @ 23.3 bar g | |

| Minimum working pressure | 0°C | |

| Minimum working temperature | 1.5 bar g | |

| Maximum working back pressure | Not to exceed 80% of upstream pressure | |

| Design maximum cold hydraulic test pressure | 60 bar g |

Pressure/Temperature Limits (ISO 6552) - Flanges ASME

| categorization | parameters | particulars |

|---|---|---|

| ASME Class 600 | Valve body design pressure | ASME Class 600 |

| PMA Maximum Allowable Pressure | 99.3 bar g @ 38°C | |

| TMA Maximum Allowable Temperature | 450°C @ 54.8 bar g | |

| Minimum permissible temperature | -50°C | |

| PMO Maximum Working Pressure | 46 bar g | |

| TMO Maximum Operating Temperature | 450°C @ 46 bar g | |

| Minimum working pressure | 0°C | |

| Minimum working temperature | 1.5 bar g | |

| Design maximum cold hydraulic test pressure | 149 bar g | |

| ASME Class 300 | Valve body design pressure | ASME Class 300 |

| PMA Maximum Allowable Pressure | 49.6 bar g @ 38°C | |

| TMA Maximum Allowable Temperature | 450°C @ 27.4 bar g | |

| Minimum permissible temperature | -50°C | |

| PMO Maximum Working Pressure | 33 bar g | |

| TMO Maximum Operating Temperature | 450°C @ 27.4 bar g | |

| Minimum working pressure | 0°C | |

| Minimum working temperature | 1.5 bar g | |

| Maximum working back pressure | Not to exceed 80% of upstream pressure | |

| Design maximum cold hydraulic test pressure | 74.4 bar g | |

| ASME Class 150 | Valve body design pressure | ASME Class 150 |

| PMA Maximum Allowable Pressure | 19 bar g @ 38°C | |

| TMA Maximum Allowable Temperature | 450°C @ 4.6 bar g | |

| Minimum permissible temperature | -50°C | |

| PMO Maximum Working Pressure | 14 bar g | |

| TMO Maximum Operating Temperature | 450°C @ 4.6 bar g | |

| Minimum working pressure | 0°C | |

| Minimum working temperature | 1.5 bar g | |

| Maximum working back pressure | Not to exceed 80% of upstream pressure | |

| Design maximum cold hydraulic test pressure | 28.5 bar g |

Weight (approximate) kg

| sizes | whorl of fingerprint | socket welding | ASME 150 | ASME 300 | Flanges ASME 600 | PN40 | PN100 |

|---|---|---|---|---|---|---|---|

| ½" (DN15) | 1.38 | 1.49 | 2.46 | 2.96 | 3.06 | 3.06 | 4.36 |

| ¾" (DN20) | 1.64 | 1.64 | 3.16 | 4.06 | 4.26 | 3.96 | 6.26 |

| 1" (DN25) | 1.90 | 1.90 | 4.16 | 5.16 | 5.46 | 4.86 | 8.16 |

Installation Instructions

The TDS46M is designed to be mounted horizontally with the heat shield on top.

If there is back pressure downstream, it is recommended that a check valve be installed.

If discharging directly to the atmosphere, it is recommended that a silencer be installed downstream.

For ease of maintenance, it is recommended that shut-off valves be installed upstream and downstream of the trap.

Ordering Instructions

Example: 1 - Spirax Sarco DN15 TDS46M Thermodynamic Steam Trap with PN40 Flange Connection.

Spare Parts

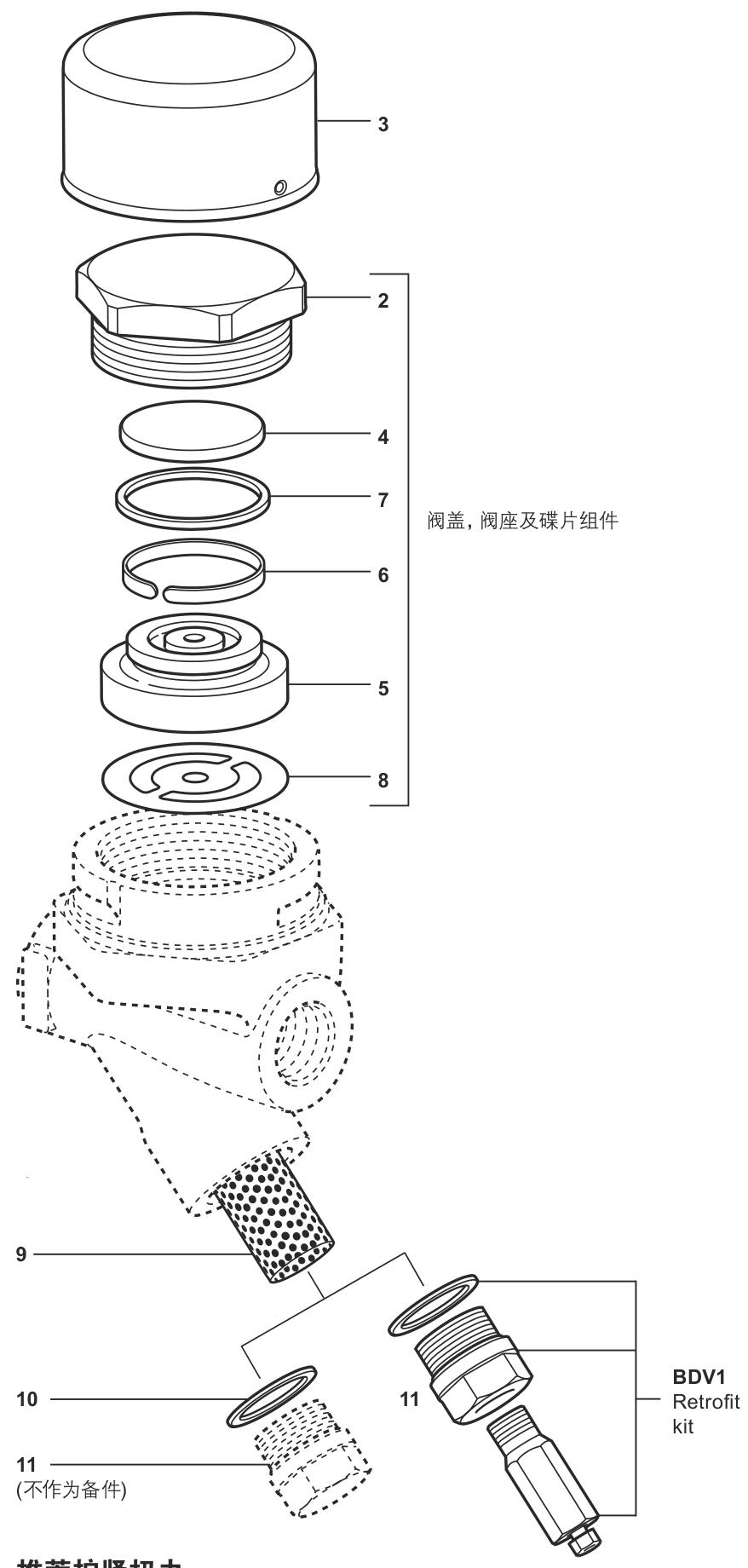

The solid part of the diagram is available for spare parts, the dotted part is not provided as spare parts.

- heat shield

- Bonnet, seat and disk assemblies (2, 4, 5, 6, 7, 8)

- Strainers and gaskets (9, 10)

- Gasket set (3 sets) (8, 10)

- BDV1 Drain Valve Assembly

Ordering Spare Parts: Order spare parts according to the above instructions, specifying the trap size and model number.

Example: 1-Bonnet, seat and disc assembly for Spirax Sarco DN15 TDS46M thermodynamic steam trap.