With the wave of industrial automation sweeping the world, control valves, as the "nerve center" of process control, have a direct bearing on production efficiency, product quality and operating costs in terms of performance and reliability. With a century of engineering experience, Spirax Sarco Engineering (China) Co., Ltd. has launched a series of general industrial control valves, which provide precise, efficient and sustainable control solutions for various industries with excellent design and innovative technology.

Why Choose Spirax Sarco General Purpose Industrial Control Valves?

In industrial production, a stable and reliable control valve can bring multiple values:

- - Enhancing Product Quality: High-precision control ensures stable process parameters, reduces product fluctuations and guarantees consistency.

- - Improve process efficiency: Accurately regulates fluid flow and pressure, reduces energy loss, and optimizes production rhythms.

- - Reduced overall costs: Durable design extends service life, reduces maintenance frequency and downtime, and significantly lowers total life cycle costs.

Core product range: meeting diversified industrial needs

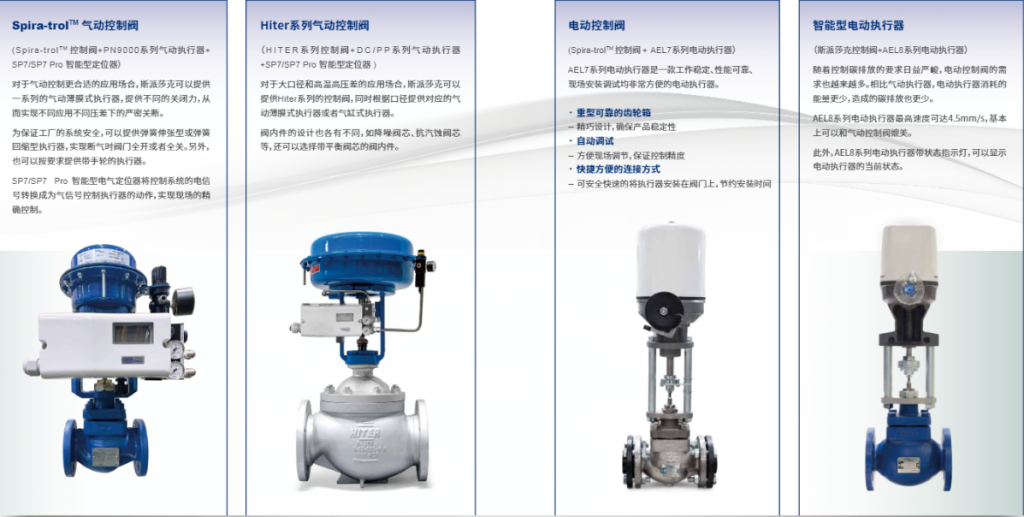

Spirax Sarco's general industrial control valves are available in two main ranges to suit different applications:

1. Spira-trol™ 2-way control valve

- - type: 2-way control valves in accordance with ANSI or EN standards

- - Valve body materialDuctile iron, carbon steel, stainless steel, alloy steel, suitable for a variety of media

- - Caliber range: DN15-DN300 (½"-12")

- - connection method::

- - Flange: PN16-PN100, ANSI125-ANSI600

- - Thread: BSP, NPT

- - Welding: socket welding

- - Flow Rate CharacteristicsEqual percentage, linear, fast start, flexible matching of process curves

- - Special ConfigurationsNoise-reducing spools, soft-seal valve seats, balanced spools, etc., to cope with complex working conditions.

2. HITER 2-way control valve

- - type: 2-way control valves in accordance with ANSI or EN standards

- - Valve body materialCarbon steel, stainless steel, alloy steel, high pressure and high temperature resistant environment

- - Caliber rangeDN15-DN400 (½"-16"), larger diameters to meet high flow requirements

- - connection method::

- - Flange: PN16-PN400, ANSI150-ANSI2500

- - Thread: BSP, NPT

- - Welding: butt welding, socket welding

- - Flow Rate Characteristics: Equal percentage, linear, modified parabolic, fast open, covering finer adjustment needs

- - Special ConfigurationsMulti-stage squirrel cage valve spool, anti-cavitation design, etc., to adapt to the extreme working conditions of high pressure difference.

Technical Highlights: Innovative Design Drives Superior Performance

Spirax Sarco control valves are designed with details to show engineering strength, and core strengths include:

High precision control and stability

- - Multiple flow characteristics: Provides 4 types of characteristics: equal percentage, linear, modified parabolic, and fast-open, which can be precisely matched to the load to ensure process stability.

- - Intelligent Positioning SystemSP7/SP7 Pro Intelligent Positioner: SP7/SP7 Pro Intelligent Positioner realizes accurate signal conversion, one-key debugging function simplifies the operation, and the air consumption is only 5% of the traditional positioner, and the annual energy saving is up to 474KWh (calculated according to the 8,000 hours of operation).

Durable and low-maintenance design

- - Reinforced stem seal: Precision-machined stem with V-shaped PTFE or high-temperature graphite seals, with self-contained wiper ring cleaning function to prevent the intrusion of impurities and extend sealing life.

- - Wear-resistant construction: Squirrel cage compression seat self-centering design reduces assembly deviation; large flow path design reduces fluid velocity and reduces erosion and noise.

Solutions for extreme conditions

- - noise reduction technology: Continuous absorption of pressure drop energy through multi-stage squirrel cages to keep flow rates within safe limits and reduce aerodynamic noise.

- - Anti-cavitation design: Optimize the flow channel structure to control the pressure within the critical value (Pvc) to avoid cavitation damage to the valve body.

- - Adaptation to special environmentsExtended bonnet for high/low temperature scenarios, stainless steel bellows seal for zero leakage and high temperature requirements.

Driving method: flexible adaptation to automation systems

- - Pneumatic actuatorMulti-spring full rolling diaphragm design, low hysteresis, quick response, optional spring extension/retraction type to ensure safe action in case of air break.

- - Electric actuator::

- - AEL7 Series: Heavy-duty gearboxes with automatic commissioning function, easy to install and suitable for regular working conditions.

- - AEL8 Series: High speed response (4.5mm/s), low energy consumption and low emissions, with status indicator, in line with low-carbon production requirements.

Spirax Sarco Commitment: A Sustainable Industrial Future

From precise control to energy saving, Spirax Sarco's universal industrial control valves always take "sustainable development" as the core. Through modular design to reduce the number of parts, intelligent positioner to reduce energy consumption, durable structure to extend the service life, not only to create economic value for customers, but also to help industrial production to green, efficient transformation.

Spirax Sarco - Total Steam Solutions Expert for Industrial Controls - works with you to build an efficient, reliable and sustainable industrial future.