Spirax Sarco Spirax Sarco Fig 3616 Austenitic Stainless Steel Filters

Brand authorization

- Rapid response service

- Professional team support

- Flexible return and exchange policy

Spirax Sarco Fig3616 Austenitic Stainless Steel Strainer - DIN material, is a Y-shaped strainer in austenitic stainless steel with integral flange and flanged bonnet. Standard stainless steel strainer: 0.8mm pore size for DN15 to DN80, 1.6mm pore size for DN100 to DN200. Other apertures and mesh sizes and Monel strainers are available. If required, threaded holes can be drilled on the valve cover of the filter to connect a drain valve or discharge valve. If required, the valve body can also be drilled with threaded holes for pressure connections.

Sizes and pipe connections

DN15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200, standard flange BS4504 PN 16.

Drain or discharge valve and pressure connection

The bonnet can be drilled with threaded holes for a drain or bleeder valve. The valve body can also be drilled for connection to a pressure gauge.

restrictive condition

The connection dimensions are as follows:

| Filter caliber | bleeder valve | venting valve | pressure port |

|---|---|---|---|

| DN 15 and 20 | 3 / 8 " | 3 / 8 " | ¼" |

| DN 25 and 32 | ½" | ½" | ¼" |

| DN 40 and 80 | ¾" | ¾" | ¼" |

| DN 100 and 200 | 1" | 1" | ¼" |

| Valve body design conditions | PN16 |

|---|---|

| PMA - Maximum Allowable Pressure | 15 bar g |

| TMA- Maximum Design Temperature | 300 °C |

| Minimum working temperature | -10 °C |

| Maximum cold test water pressure | 24 bar g |

Scope of work

There are unavailable areas for this product, and its operating range is limited by temperature and pressure, with specific requirements in the temperature (°C) and pressure (bar g) ranges associated with the saturated vapor profile, as shown in the corresponding intervals for the temperature range of 0 - 300 °C and the pressure range of 0 - 16 bar g.

material (that sth is made of)

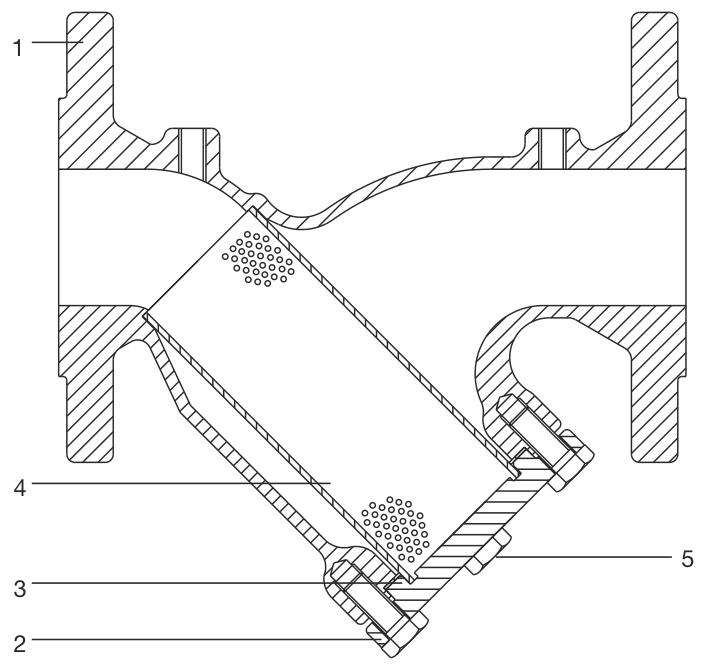

| Item | Part | material (that sth is made of) |

|---|---|---|

| 1 | valve body | Austenitic stainless steel EN10213 pt 4 1.4408 |

| 2 | bonnets | Austenitic stainless steel EN10088 pt 3 1.4401 |

| 3 | gaskets | Reinforced flake graphite |

| 4 | filter | Austenitic stainless steel ASTM A240 316L |

| 5 | bolt (male component of nut and bolt) | Austenitic stainless steels EN ISO 3506 A2-70 |

Certification

Material standard certificates for body and bonnet EN 10204 3.1.B are available and should be specified when ordering.

(K_{v}) value

| caliber | DN15 | DN20 | DN25 | DN32 | DN40 | DN50 | DN65 | DN80 | DN100 | DN125 | DN150 | DN200 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hole sizes 0.8, 1.6 and 3 mm | 5 | 8 | 13 | 22 | 29 | 46 | 72 | 103 | 155 | 237 | 340 | 588 |

| Mesh 40 and 100 | 5 | 8 | 13 | 22 | 29 | 46 | 72 | 103 | 155 | 237 | 340 | 588 |

| Number of items 200 | 4 | 6 | 10 | 17 | 23 | 37 | 58 | 83 | 124 | 186 | 268 | 464 |

Conversion formula: (C_{v}(UK) = K_{v} × 0.963); (C_{v}(US) = K_{v} × 1.156)

Weight (approximate)

| caliber | weights |

|---|---|

| DN15 | 2.1 kg |

| DN20 | 2.9 kg |

| DN25 | 3.8 kg |

| DN32 | 6.6 kg |

| DN40 | 9.0 kg |

| DN50 | 10.5 kg |

| DN65 | 17.5 kg |

| DN80 | 20.0 kg |

| DN100 | 24.0 kg |

| DN125 | 38.0 kg |

| DN150 | 50.5 kg |

| DN200 | 88.0 kg |

safety information

For detailed information, refer to the Installation and Maintenance Guide (IM-S60-18) supplied with the product.

- Pressure: Before filter maintenance, the presence of pressure in the line should be considered. It should therefore be ensured that the pressure has been cut off and safely vented to atmosphere prior to maintenance. This can be achieved by installing a Spirax Sarco Pressure Relief Valve DV (see relevant product literature for details). Do not assume that the system has been relieved even if the pressure gauge reads zero.

- TEMPERATURE: Allow time after the pipe cutoff for the temperature to drop to ambient temperature to prevent burns. Protective clothing (including safety glasses) should also be worn.

- NOTE: There is a thin stainless steel support ring in the gasket of the filter cover, please remove it carefully.

mounting

Refer to the Installation and Maintenance Guide (IM-S60-18) supplied with the product for detailed information. The filter should be installed horizontally in the direction of flow on the housing. When applied to horizontal piping for steam or gases, the filter body should be kept in a horizontal plane, while in liquid systems, the body should be in a vertical downward position. To facilitate maintenance and replacement, suitable shut-off valves should be installed upstream and downstream of the filter. Before installation, remove all protective parts, slowly open the shut-off valve until normal working conditions are reached and check for leakage.

protect and maintain

Refer to the Installation and Maintenance Guide (IM-S60-18) supplied with the product for detailed information. The filter can be serviced directly on the pipeline if safety procedures are observed. When servicing, it is recommended to use new gaskets and spare parts.

take care of

This product is recyclable and does not harm the environment when disposed of properly.

place an order

Example: 1 - Spirax Sarco DN 40 Fig 3616 filter, BS 4504 PN 16 flange connection, 0.8 mm pore size stainless steel screen.