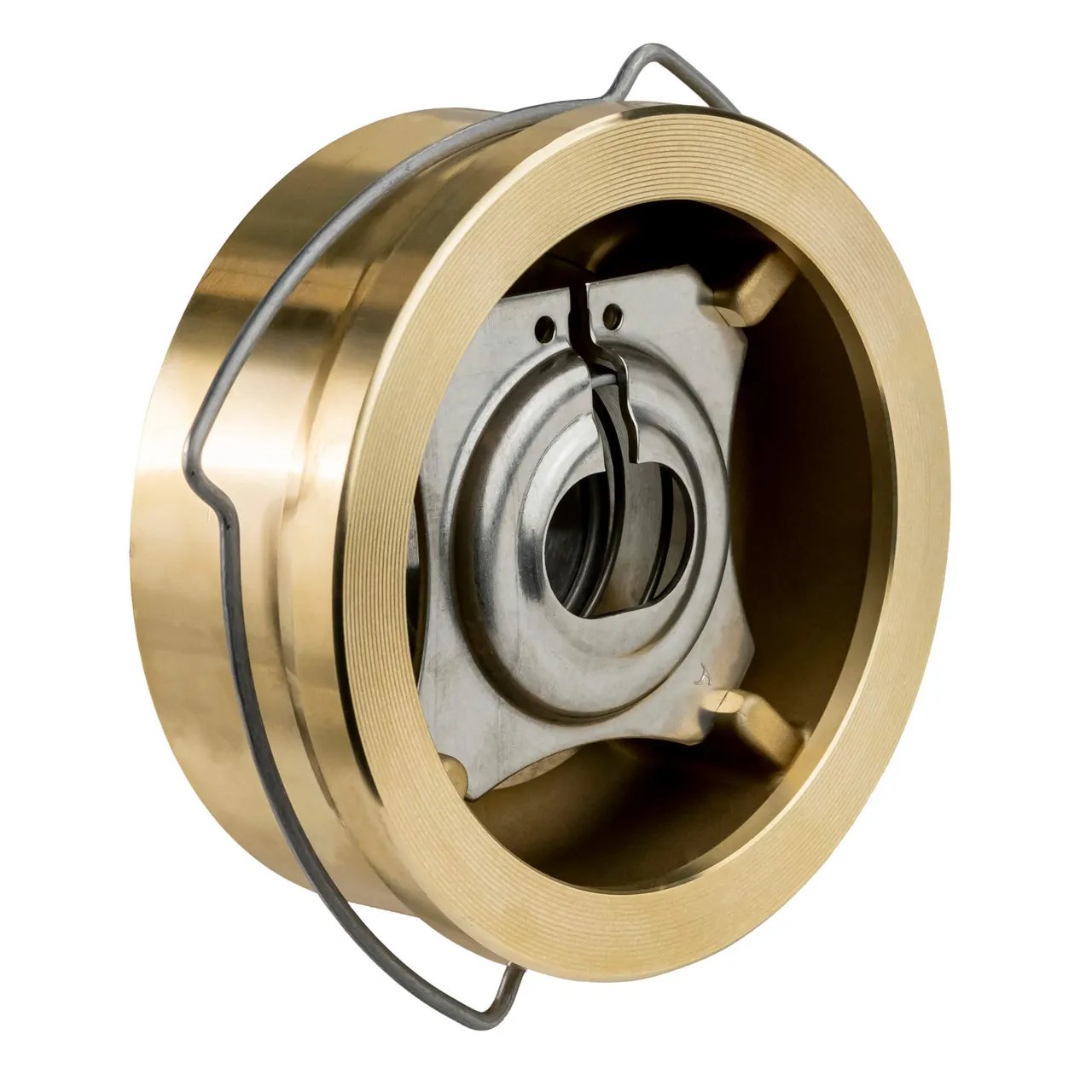

GESTRA GESTRA RK71 Non-return valve Brass check valve

Brand authorization

- Rapid response service

- Professional team support

- Flexible return and exchange policy

The GESTRA RK71 non-return valve is a classic DISCO® series product under the German GESTRA brand, designed for industrial piping systems to provide reliable protection against backflow. As a high quality brass non-return valve, it is suitable for pressure ratings from PN6-16 and diameters from DN15-100 and ensures unidirectional flow of liquids, gases and vapors.GESTRA RK71 non-return valves are known for their compact design and durable materials and are widely used in heating, HVAC and compressed air systems.

Product specifications and technical parameters

GESTRA RK71 non-return valves have a wafer-type construction that is easy to clamp between flanges and complies with international standards to ensure easy installation. Detailed specifications are given below:

- Nominal pressure (PN):: 6/10/16 barg.

- Nominal diameter (DN): 15-100 mm (equivalent to 1/2" - 4").

- temperature range: -60°C to 250°C (depending on pressure and media, up to 100°C for standard heating applications).

- Cracking Pressure: 10-18 mbar for spring-loaded versions, 2.5-6.5 mbar for spring-less versions (depending on DN size).

- Size & Weight(Example):

- DN 15: Length 16 mm, diameter 40 mm, weight 0.09 kg.

- DN 50: length 40 mm, diameter 95 mm, weight 1.05 kg.

- DN 100: length 60 mm, diameter 152 mm, weight 3.2 kg.

- Flange connection standard: DIN/EN BS EN 1092-1 (Form B1), BS 10 Table D/E/F.

- Pressure Temperature Ratings(RK71 PN16 CW617N example):

Temperature (°C) 20 120 200 250 Pressure (barg) 16 16 14 13

The overall length of the GESTRA RK71 check valve is in accordance with EN 558-1 Series 49. The extremely short design reduces installation space requirements. For further technical details please refer toOfficial Data Sheet PDFThe

Material and structural characteristics

GESTRA RK71 non-return valves are made of high-quality materials to ensure corrosion resistance and long life:

- Body, Seat and Guide Ribs: CW617N hot pressed brass (ASTM C38000 equivalent), corrosion resistant and suitable for non-hazardous media.

- Valve discs, springs and retainers: 1.4571 austenitic stainless steel (AISI 316 Ti equivalent), supplied with metal-to-metal seals (optional EPDM, FPM or PTFE soft seals for water, steam, mineral oils or corrosive media).

- Other components: The spring retainer and centering ring are made of stainless steel to ensure stable operation.

Key features include:

- Spring-assisted design: Allows installation in any position (horizontal, vertical or inclined), the springless version is limited to vertical upward flow.

- Low pressure drop and low noise: Four guide ribs reduce wear and optimize fluid passage.

- Compact and lightweight: Weight is much lower than conventional valves, reducing installation costs.

- standards-compliant: Leakage tested to DIN EN 12266-1, PED 97/23/EC certified for Fluid Group 2 media. Without own ignition source, can be used around Ex zones (see ATEX declaration for details).

- Antistatic option: Anti-static connections can be customized and added.

These features allow GESTRA RK71 brass check valves to excel in industrial applications and reduce maintenance requirements. Chemical resistance details are available atGESTRA official website technical supportThe

Areas of application and advantages

GESTRA RK71 non-return valves are used in a wide range of industrial scenarios to ensure safe and efficient system operation:

- Heating and HVAC systems: Prevents backflow of hot water or steam, suitable for compressed air and ventilation ducts.

- Steam and condensate systems: Provides reverse run protection in parallel pump arrangements.

- Industrial Piping: For one-way control of liquids, gases and vapors to prevent backflow contamination or damage to equipment.

- (sth. or sb) else: Compressed air systems, sanitary engineering and air conditioning technology.

Advantage:

- high reliability: Metal seals ensure a tight seal, and soft seal options boost leakage rates to Class A.

- cost-effective: Low installation costs, low pressure drop and reduced energy consumption.

- easy maintenance: Compact design for easy removal and replacement.

For minimum volumetric flow requirements for specific applications, refer to theGESTRA Non-Return Valves Brochure PDFto ensure stable opening of the valve disc.

Certification and Documentation

- accreditation: CE marking (PED 97/23/EC), material test report EN10204-2.2 optional.

- Related Documents::

- RK71 Product Data Sheet - Includes pressure drop charts and installation instructions.

- GESTRA Complete Non-Return Valve Brochure - Detailed application examples and technical diagrams.

- GESTRA official website product page - Latest updates and support.