Spirax Sarco FTS14 Maintenance kit 11452180

¥1,600.00

Brand authorization

- Rapid response service

- Professional team support

- Flexible return and exchange policy

- Document Number: IM-P145-02 ST Issue 1

- branding: Spirax Sarco

- Copyright InformationCopyright 2005

- Scope of application: FTS14 series austenitic stainless steel float steam traps in 1/2" (DN15), 3/4" (DN20) and 1" (DN25) sizes.

1. Security information

Compliance with these operating instructions and proper installation, commissioning, and maintenance by qualified professionals are the only guarantees for the safe operation of this valve (see section 11 of the Appendix Safety Information for details). Installation must be carried out in strict compliance with pipeline routes, plant building installation guidelines and safety codes, using the correct tools and with the necessary safety equipment.

1.1 Warnings

- The bonnet gasket contains a sharp-edged stainless steel support ring, which may cause cuts if not handled or disposed of carefully.

- Fluorinated rubber "O" rings are used for315°C (599F) and higher temperaturesEnvironment, may decompose to produce hydrofluoric acid; avoid skin contact and inhalation of the acid, which may cause skin burns and damage to the respiratory system.

1.2 Segregation requirements

- When closing the shut-off valve, consider the safety of the rest of the system and the operator, and equip it with ventilation isolation equipment, protective devices or alarms if necessary.

- Close the shut-off valve gradually to avoid vibration of the system caused by too rapid operation.

1.3 Pressure control

- Make sure the valve is connected to the pressure system before servicing.Total isolation, and completely vent the pressure in the isolated section to atmosphere (installation of a Spirax Sarco DV type pressure relief valve is recommended, see corresponding datasheet for details).

- It is strictly prohibited to judge that the pressure has been completely relieved only by the pressure gauge displaying "zero", and it should be confirmed by professional pressure relief operation.

1.4 Temperature protection

- Valves need to be cooled to room temperature after isolation to prevent scalding; protective clothing and protective goggles should be worn during operation.

1.5 Waste disposal

- The whole product can be recycled, and standardized treatment will not cause ecological harm, only the fluorinated rubber "O" ring needs special treatment:

- The waste portion can be landfilled, subject to national or local environmental regulations.

- The waste fraction may be incinerated, subject to compliance with the use of scrubbers to remove hydrogen fluoride from combustion.

- Fluorinated rubber "O" rings are partially insoluble in aqueous solutions.

2. Product profile

2.1 Core functions

The FTS14 austenitic stainless steel float steam trap has a built-in automatic air vent to ensure that process equipment is in optimal working condition by efficiently discharging condensate and removing air.

2.2 Flow direction and installation flexibility

- Standard flow: Horizontal connection with right-to-left (R-L) flow direction.

- Reorientation of flows: By removing the 4 bonnet bolts and rotating the bonnet, it can be switched to flow horizontally from left to right (L-R), vertically upward, or vertically downward (gaskets need to be replaced for adjustment).

- Note: Further technical details are detailed in Technical Information Brochure TI-P145-01.

2.3 Additional function selection

| Available types | Core add-ons |

|---|---|

| FTS14X | Built-in filters to protect internal components from impurity damage |

| FTS14-C | Built-in broken steam vapor lock device + thermostatic air venting valve for possible vapor lock scenarios (see section 3.11 for details); bonnet can be drilled and tapped (1/8" BSP thread) for installation of PT100 and other temperature sensors, factory with stainless steel plugs |

2.4 Orifice and pipe connections

| connection standard |

|---|

| Threaded connection: BS 21, DIN 2999 (metric) or NPT (ANSI B 1.20.1, US) |

| Socket weld connections: 3799 Class 3000 or DIN 3239 |

| Flange connection: DN15/20/25 according to ANSI B 16.5 Class 150/300 or EN 1092-1/PN16/25 |

| Note: Other connection methods are subject to consultation with Spirax Sarco. |

2.5 Limitations (ISO 6552)

| parameters | norm |

|---|---|

| Valve body design pressure | PN25 |

| Maximum Permissible Pressure (PMA) | 25 bar g (363 psi g) |

| Maximum Permissible Temperature (TMA) | 300°C (572°F) |

| Maximum operating temperature (TM0) | 225°C (437°F) |

| Minimum working temperature | -20°C (-4°F) (consult factory for lower temperatures) |

| Maximum cold test pressure | 37.5 bar g (544 psi g) |

2.6 Scope of work

- Pressure range: Refer to the "Scope of Work Diagram", which clearly indicates the "Prohibited Areas" (areas where use may cause damage to the internal parts).

- Key notes::

- PM0: Maximum working pressure of steam.

- Zone A-B: Suitable for flange connection (PN16/25, ANSI 300), threaded connection, socket weld connection.

- Zones A-C: For flanged connections (ANSI 150).

- The maximum working pressure/temperature of a sanitary clamp connection is limited by the specification of the gasket or clamp used.

- Maximum differential pressure (PMX)::

Available types Maximum differential pressure FTS14 - 4.5 4.5 bar FTS14 - 10 10 bar FTS14 - 14 14 bar

2.7 Material specifications

| Part | Material specifications |

|---|---|

| Valve body and bonnet | Austenitic stainless steel (316) to EN 10213-4 (1.4408), ASTM A351 CF8M |

| Bonnet bolts | Stainless steel according to BS EN 3506 A2-70 |

| Bonnet Gasket | Reinforced sandwich graphite |

| "O" ring | Nitrile rubber (FDA approved) |

| internal part | stainless steels |

3. Installation

NOTE: Before installation, you must carefully read Section 1, Safety Information, and refer to this guide, the product nameplate, and the technical manual to verify that the product meets the installation requirements.

3.1 Pre-inspection

- Confirm the maximum pressure and temperature limits of the product, which need to match the working conditions of the installation system; if the product limits are lower than the system working conditions, additional safety devices need to be installed in the system to prevent overpressure.

- Check that the installation location meets the requirements and confirm that the flow direction is consistent with the design.

- Remove the plastic protective covers from all ports.

3.2 Emission safety

- If the trap is discharged directly to atmosphere, make sure that the vent is located in a safe area (discharge liquid temperatures can reach up to 100°C (212°F) to avoid the risk of scalding).

3.3 Core installation requirements

- The float arm must be level to ensure that the float can be raised and lowered vertically; the side of the valve marked "TOP" must be at the top (all installation flow directions are subject to this requirement).

- The trap is to be installed at the outlet of the steam system.world of mortalsIf the trap is not installed, steam may flow in the direction of condensate in the piping under low load conditions and enter the trap, causing steam vapor lock.

3.4 Back pressure treatment

- If there is back pressure on the condensate recovery line to which the trap discharges (e.g., if the condensate line needs to be lifted), it is necessary to install a check valve downstream of the trap (Spirax Sarco DCV41 is recommended, see Fig. 4) to prevent water from accumulating on the piping when the inlet pressure is reduced or when the steam line is shut off.

3.5 Bypass Installation Recommendations

- Installation of a bypass is not recommended: Bypasses can pose a risk of leakage, or failure of the trap due to forgotten closure, wasted steam leakage, or even elevated condensate recovery line pressure.

3.6 Welding requirements

- If the trap is to be welded to pipingOnly arc welding is permittedThe valve can be welded without removing the internal parts; other welding methods may result in deformation of the valve body or damage to the internal parts.

3.7 Vapor lock prevention (added in section 3.11)

- Installation Location: Float traps should be installed as close as possible to the outlet of the equipment to be drained, reducing the length of piping between the condensate outlet and the trap, and avoiding steam-filled piping that could cause vapor lock (vapor lock can lead to water buildup in the system and reduce equipment efficiency, similar to airlock in a water system).

- High-risk scenarios: Rotary Simplifiers or other equipment that requires condensate to be discharged through a drop tube/siphon, prone to vapor lock.

- Solution: Install an automatic air venting valve and a vapor lock release valve (SLR), specifically:

- Turning the SLR spindle counterclockwise opens the valve, factory standard setting is 1/2 turn, which corresponds to a "bypass" flow rate of 22 kg/h @ 10 bar steam.

- SLR Flow Adjustment: Rotate the shaft counterclockwise to increase bypass flow and clockwise to decrease bypass flow.

- WARNING: SLR should not be used with high load "blowdown" steam as this will shorten trap life; consult Spirax Sarco when blowdown steam is required.

3.8 Environmental exposure protection

- If the trap is installed in the open air or in a low-temperature exposure environment, it is necessary to insulate the valve body or install a separate small thermostatic trap drain to prevent freeze damage to the valve body.

3.9 Maintenance space reservation

- Sufficient space needs to be reserved at the time of installation to ensure that the valve body can be removed subsequently (from the bonnet), depending on the size of the reservation:

- DN15(1/2"), DN20(3/4"): Reserve 135mm(5.6")

- DN25(1"): reserved 145mm

4. Commissioning

- Before commissioning, it is necessary to confirm that the system has been fully installed in place, and the alarm and protection devices (such as pressure relief valves, check valves) have been tested and are functioning properly.

- The commissioning process should follow the principle of "low pressure followed by high pressure, room temperature followed by warming", and gradually verify that the condensate discharge and air exclusion functions of the trap are normal, and confirm that there is no leakage and no vapor lock phenomenon.

5. Operation

5.1 Principles of operation

FTS14 isContinuous emission typetrap, the workflow is as follows:

- When the system starts, the thermostatic air venting valve discharges air from the main valve to prevent air locking.

- When hot condensate enters the trap chamber, the air vent valve closes, the float rises with the condensate level, and the main valve is opened by the arm lever device to discharge the condensate.

- When steam enters the trap chamber, condensate is reduced and the float drops, closing the main valve and stopping steam leakage.

5.2 Operational advantages

- It can withstand high loads when starting and is well sealed against water hammer and system vibration.

- If vapor lock occurs during operation, it is necessary to replace the trap with one with an SLR (vapor lock release valve) (e.g., FTS14-C) and adjust the SLR as required in Section 3.11.

6. Maintenance

NOTE: Section 1, Safety Information, must be read carefully before servicing to ensure that piping is disconnected, pressure is fully relieved, and the valve body is cooled to room temperature.

6.1 General maintenance requirements

- Before maintenance, it is necessary to cut off the pipeline, discharge the pressure medium safely to the atmosphere, and operate the valve after it has cooled down.

- When reinstalling ensure that all bonding surfaces are clean, replace damaged seals (e.g. "O" rings, washers) and tighten the bolts to the recommended torque (see Table 1).

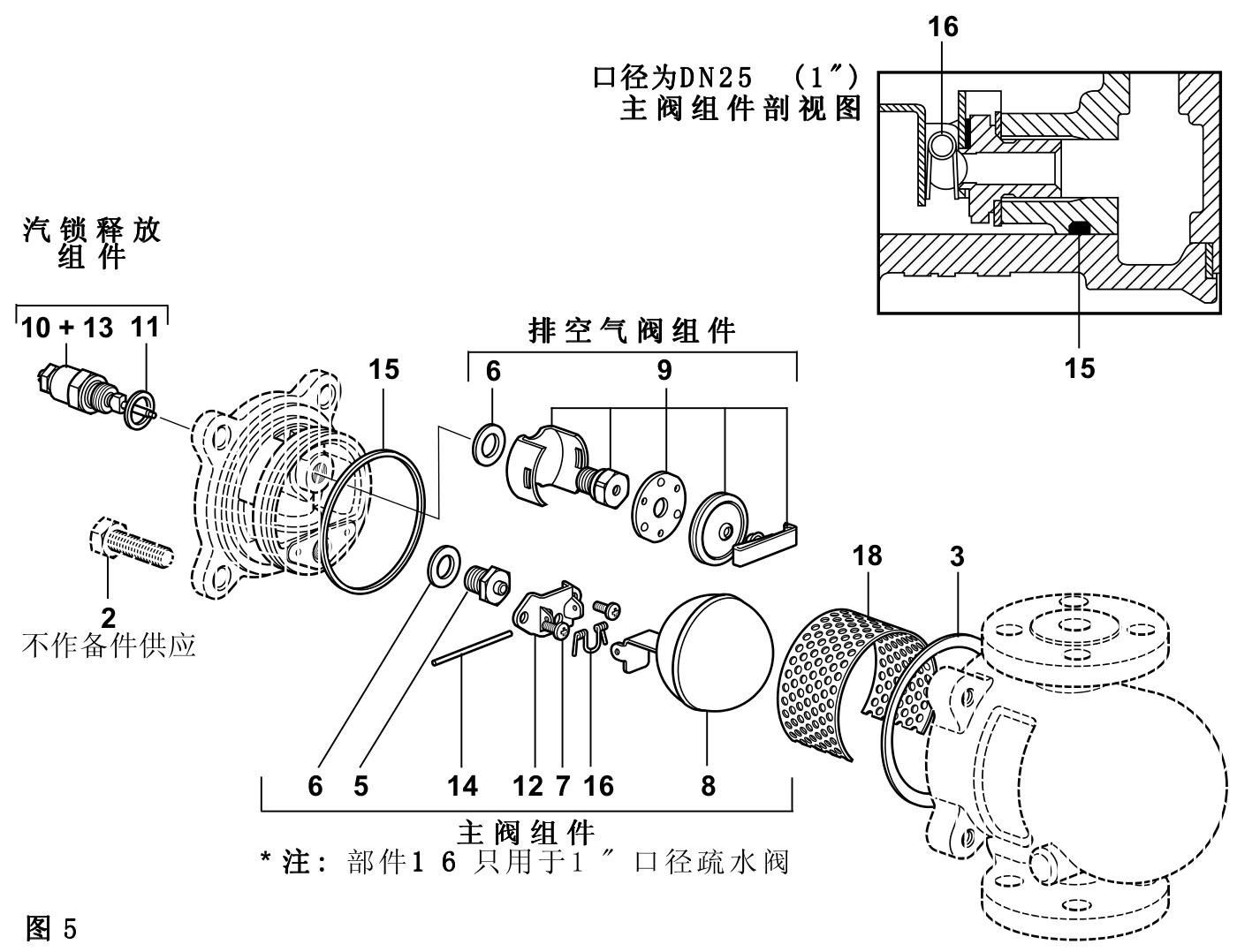

- The repair procedure needs to be performed in conjunction with Figure 5 on page 8 (cutaway view of main valve assembly).

6.2 Main Valve Assembly Assembly Procedure

- Remove the bonnet bolts (part 2), insert two screwdrivers into the gap between the valve body and bonnet, pry out the valve body and align the bolt holes.

- Remove the pivot pin (part 14) and float assembly (part 8).

- Remove the two main valve assembly screws (part 7) and the swivel bracket (part 12).

- Remove the main valve seat (part 5), replace with a new main valve seat and matching gasket, and tighten to the recommended torque (see Table 1).

- Note: Valve spring (Part 16) is only available for traps with DN25 (1") diameter.

- Tighten the main valve assembly screws (part 7) to the recommended torque and install the swivel bracket (part 12); reassemble the float assembly (part 8) and swivel pin (part 14).

- Install a new "O" ring (part 15) in the valve body, making sure that the contact surface is clean and undamaged; an appropriate amount of compliant lubricant may be applied to aid in installation.

- Install the bonnet, replace the bonnet gasket (part 3) with a new one, and tighten the bonnet bolts (part 2); make sure that the "TOP" mark on the valve body is located at the uppermost end (all installation flow directions must be observed).

6.3 Installation Procedure for Evacuation Valve Assemblies

- Remove the spring clip, fluid bladder, and spacer.

- Unscrew the air exhaust valve seat (part 9) and gasket (part 6).

- Install new gaskets, seats and brackets and tighten to recommended torque (see Table 1).

- Reinstall the spacer, fluid bladder, and spring clips, making sure that the evacuation air valve is positioned horizontally and that there is clearance between the bracket and the valve cover.

6.4 Filter replacement (in installed condition)

- Remove the valve cover bolts (part 2) and pry out the valve body with two screwdrivers.

- Remove the filter and clean it (if reusable) or just replace it with a new one.

- When installing a new strainer, make sure it is located between the two protruding edges on either side of the outlet end.

- Reinstall the valve body, replace the "O" ring (part 15) and bonnet gasket (part 3) with new ones, and tighten the bonnet bolts to the recommended torque (see Table 1).

7. Spare parts

7.1 List of available spare parts

- Repair kit: Contains part 6 (2 sets), part 7 (2 sets), part 8, part 9, part 12, part 14 (available on some models only), part 18.

- Washer set: Contains part 3 (3 pieces), part 15.

- Note: Spare parts are based on the parts marked with "solid lines" in the drawing attached to the manual, and spare parts are not available for the parts marked with "dotted lines".

7.2 Spare parts ordering requirements

- The following information should be specified when ordering: trap diameter (e.g. DN15/20/25), model number (e.g. FTS14-X/C), and pressure range (e.g. 4.5/10/14 bar).

- Ordering example: 1 repair kit for Spirax Sarco 1/2" (DN15) FTS14-4.5 steam trap.