In steam systems, stable and accurate pressure control is the key to efficient system operation, equipment safety and product quality. The Spirax Sarco 25P series pilot-type pressure reducing valves have become an indispensable component of steam systems due to their excellent performance and rich functionality.

Superior Features of the 25P Series Pilot Valve Type Pressure Reducing Valve

The unique features of the Spirax Sarco 25P series of pilot-type pressure reducing valves are responsible for the wide range of applications in steam systems.

- - multifunctional integration: One or more pilot valves can be installed or interchanged in the same valve body, allowing temperature control, upstream pressure control or remote on/off control while stabilizing pressure reduction. These functionally variable valves can either be supplied or simply assembled on site.

- - Precise pressure control: Equipped with three different colored springs, yellow (0.2bar g-2.1bar g), blue (1.4bar g-7.0bar g), and red (5.6bar g-14.0bar g) for precise pressure control. When selecting springs with overlapping ranges, selecting a spring with a smaller range allows for better control.

- - Wide range of connectionsA wide range of threaded and flanged connection standards are available to suit different installation requirements.

- - Durable designThe patented self-cleaning guide has a long service life and is maintenance-free; the diaphragm design, which has undergone rigorous fatigue testing, avoids the sticking problem that may be caused by the use of a plunger; the valve body can be made of ductile iron or cast steel to meet the needs of different working conditions.

Why do you need to de-stress?

Pressure-reducing operations in steam systems are important from both an economic and a safety point of view.

economics

- - Steam is generated at high pressure, which increases the heat storage capacity of the boiler and its ability to handle peak loads; the specific volume of steam at high pressure is small, resulting in small delivery piping and low installation costs; it also reduces the start-up and warm-up time of the system and lowers the heat loss of the system.

- - Whereas steam is used at low pressure at the point of use, the latent heat of the steam at low pressure is large, which improves efficiency; the dryness of the steam is increased after depressurization, and the quality of the steam is improved.

safety

Steam equipment has safe working pressure requirements, and equipment operators have safety requirements for over-temperature and over-pressure. Accurate and stable pressure reduction protects the equipment from overpressure, protects the equipment operators, and ensures the quality of the product, avoiding scrap due to high temperatures.

25P Series Pressure Reducing Valve Principle of Operation

Before start-up, the main valve is closed and the pilot valve is opened by spring force. Steam enters the main valve diaphragm chamber through the pilot valve and part of the steam flows out through the control orifice. The control pressure in the main valve diaphragm chamber increases, opening the main valve.

As steam flows through the main valve, the downstream pressure rises and is fed back by the pressure sensing tube to act on the lower part of the pilot valve diaphragm (a downstream pressure sensing tube should be installed in order to ensure stable downstream pressure), which balances the spring force on the upper part of the diaphragm and causes the pilot valve to throttle closed gradually, maintains the pressure inside the diaphragm chamber of the main valve, controls the opening of the main valve, and delivers the proper amount of steam to maintain a stable downstream pressure. When the downstream pressure rises, the feedback pressure increases, the pilot valve closes, and the control pressure is released from the control orifice to close the main valve tightly.

Any load changes or pressure fluctuations downstream are fed back underneath the pilot valve diaphragm, which in turn regulates the opening of the main valve to ensure stable downstream pressure.

25P Series Pressure Reducing Valve Selection and Application

Selection method

- - Determine the upstream steam pressure P1 (barg), the set downstream steam pressure P2 (barg), and the maximum steam flow rate kg/h.

- - Determine the caliber of the pressure reducing valve from the selection chart (refer to the selection example).

- - Determine the body material and connection method of the pressure reducing valve.

- - In addition, it can also be selected using the Kv value, which is the flow capacity when the control valve is fully open. The Kvs values for different calibers of 25P series pressure reducing valves are as follows:

| DN15 | DN20 | DN25 | DN32 | DN40 | DN50 | DN65 | DN80 | DN100 | DN125 | DN150 |

| 3.0 | 5.5 | 8.9 | 12.0 | 17.0 | 30.0 | 48.0 | 63.0 | 98.0 | 106 | 133 |

Conversion equation: (C v(U K) = K v × 0.963), (C v(U S) = K v × 1.156)

typical application

- - Pilot valve type pressure reducing station in series: Typically when the pressure regulation ratio (ratio of upstream pressure to downstream pressure) exceeds 10:1, a two-stage pressure reducing station is used in series.

- - Parallel connection of decompression stations: Although the pressure reducing valve can be adjusted between its maximum flow rate and zero load (pressure reducing valve closed), its service life will be affected when the pressure reducing valve operates under low load conditions for a long period of time, and it is recommended to use two pressure reducing stations in parallel at this time. When the minimum load is less than the maximum amount of 10%, it is recommended to use two pressure reducing valves in parallel, using parallel connection, the system can be automatically switched between large and small load conditions.

Other Types of Series 25 Control Valves

The Spirax Sarco 25P series of pressure reducing valves comes in many varieties, and in addition to the 25P model, there are many other types to meet different needs.

- - Type 25PE: The addition of a solenoid valve E to the 25P allows for remote electronic on/off control while depressurizing.

- - Model 25BP: Back pressure reducing valve for controlling the stabilization of upstream pressure.

- - Model 25T: Self-acting temperature control valves using a 25P main valve fitted with a temperature control pilot valve T to achieve accurate control of process temperature are widely used in temperature control of various steam heat exchangers.

- - Model 25PT: The Pressure Reducing Temperature Control Valve, with the addition of a temperature control pilot valve T to the 25P, allows for temperature control of the process while reducing pressure. Its temperature pilot valve has a temperature dial for correct temperature setting and is available with a wide range of probes for different temperature ranges and capillary tubes of different lengths.

Pressure Reducing Station Solutions and Advantages

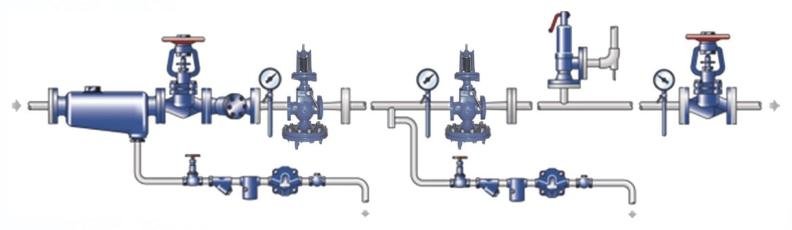

Pressure Reducing Station Components

The decompression station consists of a variety of components. Common components and information on models and specifications are listed below:

| Item | Product Description | Product Model | norm | connection method |

| 1 | stop valve | BSA2T,BSA3T | DN15-250 | - |

| 2 | vapor separator | 5, S6, S7, S8, S12, S13 | 1/2"-8" (DN15-200) | Flange, Threaded |

| 3 | Strainers and Filters | Fig33, Fig34 | 1/2" -8" (DN15-200) | flangeless |

| 4 | pressure gauge | - | - | - |

| 5 | Overview of Pressure reducing and surplussing valves | 25P | 1/2" -6" (DN15-150) | - |

| 6 | Safety Valves | SV60,SV615 | 1/2"-6" (DN15-150) | Flange, Threaded |

| 7 | Spirax Sarco Trap Monitor | ST14,16,17 | 1/2"-1" (DN15-25) | Flange, Threaded |

| 8 | Float trap | FT14, FTC32 | 1/2" -1" (DN15-25) | Flange, Threaded |

| 9 | Check Valves | DCV3 | 1/2" -1" (DN15-25) | Flange clamps |

| 10 | Globe valves (ball valves) | M10 | 1/2" -1" (DN15-25) | Flange, Threaded |

Advantages of use

- - Provides system-matched pressure reducing valve solutions for precise pressure control, improved process efficiency and product quality.

- - Professional product selection and system design, standardized design and ideal mounting configurations enable quick and easy on-site installation with reduced downtime.

Whether from the point of view of performance, function or application range, Spirax Sarco 25P series pilot-type pressure reducing valves and 25 series regulating valves show excellent quality and provide reliable guarantee for the efficient and safe operation of steam systems.